Porcelain Insulator News

by Jack H. Tod

Reprinted from "INSULATORS - Crown Jewels of the Wire", September 1978, page 21

Matt Grayson (Roslyn, N.Y.) recently sent advertising information on

the pin

type insulators being manufactured and sold by Hendrix Wire & Cable Corp.,

Milford,

N.H.

I subsequently received from the company data sheets and insulator

specimens for use in making this fairly detailed report on them. As far as I can

recall, we haven't reported these insulators in Crown Jewels before.

These

insulators are made of high-density polyethylene. Hendrix started making the

plain top versions (next page) in approximately 1970 and, after some design

changes and improvements, there are now four models of these. Starting approximately one year ago, there are four models of the Vise-Top insulators (later

page). All data, drawings and photos are courtesy of Hendrix Wire & Cable

Corp,, and for which we thank them very much.

Unless you pick up one of these

in your hand, they are identical in appearance to sky-glaze porcelains except

for a surface which is comparatively only semi-glossy. The most striking feature

is their lightness in weight (about 1/3 That of comparably rated porcelains).

You will not recognize one of these polyethylene units on a pole top except for

their outlines differing from current porcelain styles. Each unit is marked

circularly around the small base surrounding the pin hole cavity with "H.

W. & C. CORP.", The catalog number (ie. "HPI 15-B"), and several

factory code numbers, one of which appears to be the year of manufacture.

These

insulators were originally developed as a result of research studies of

component materials for use on Hendrix Aerial Cable Systems. The company

technical papers explain all this fully, but I won't bore you with the technical

part of this which engineers can best cope with. In essence, the design solves

an old problem of the erosion of cable insulation when insulated cables were

mounted on porcelain insulators -- usually necessitating the removal of cable

insulation at each point where cables were tied to the insulators. The

polyethylene insulator has a low dielectric constant which is more nearly equal

that of the cable insulation, whereas the high dielectric constant of porcelain

insulators in comparison to that of the cable insulation causes an electrical

over-stressing of the latter. The use of the more compatible materials

also essentially eliminates the radio interference problems associated with this

overstressing of the cable-to-insulator interface. Needless to say, the

insulators are also very suitable for use with bare conductors, and they meet

the A. N. S .I. requirements for radio-free insulators.

Large Image (225 Kb)

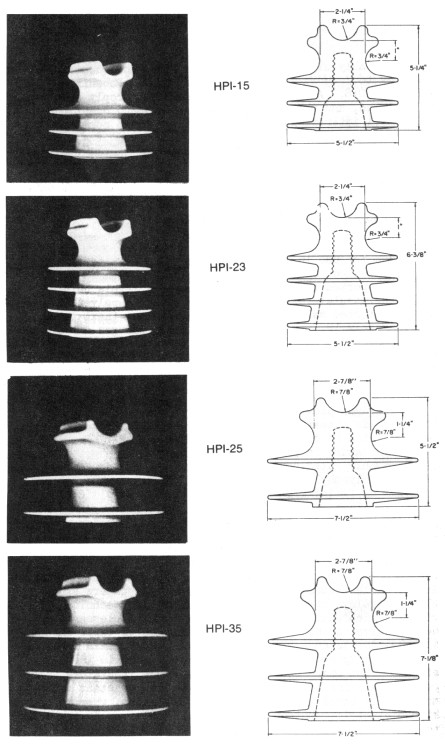

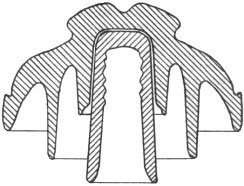

The drawings and cuts on the preceding page illustrate the plain top styles.

The HPI-15, 23, 25 and 35 styles are rated respectively at 15 Kv, 25 Kv, 25 Kv

and 35 Kv. The latter two are also available with 1-3/8" pin hole, numbered

as the HPI-25L and HPI-35L. Crowns will accept preformed tie wires.

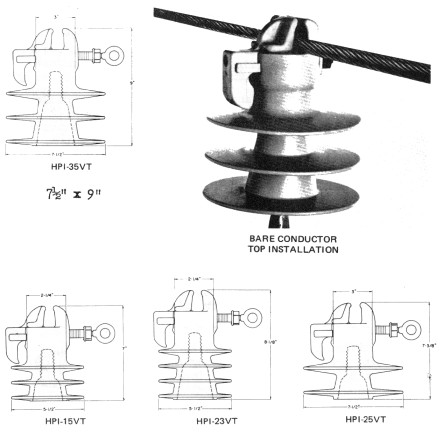

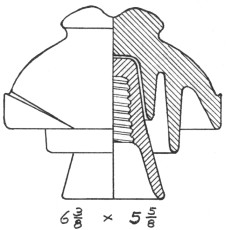

The Vise-Top units shown below on this page are very interesting items as

compared with clamp tops on porcelain pin types. Note the clasp is formed directly

in the crown of the insulator, all parts being of the same polyethylene. The

side hook of the clasp may be used for cornering positions or for horizontal

insulator mounts. The sample of the HPI-15VT (Vise-Top) received is not

identical with the HPI-15VT drawing but has a deeper and curved side groove more

like the photo and drawing of the HPI-15 plain top style.

Large Image (105 Kb)

Even for a 1-1/2" diameter cable, the clamping screw threads are engaged

at least 2". When the clamp is tightened, it is locked in place by two

detent teeth integral with the head of the clamping bolt and which bite into the

insulator crown in an irrevocable manner, The conductor is clasped by tightening

the torque bolt with a hand tool or hot stick until the ring on the end of the

bolt breaks away.

There are several byproducts of the polyethylene design which are

advantageous. First of all, the lightness in weight simplifies packing,

shipping, storage and installation. Secondly, they are essentially

indestructible in normal use, and they can be properly grouped with other forms

of vandal-proof insulators. The company furnished photos and test data on

specimens which had been mercilessly punished with shots from high-powered

rifles, buck shot, shotgun rifled slugs. I'm sure you could threw rocks and

bricks at these from 10' all day without damaging one of them to the point where

they would become unserviceable.

The sample Hendrix insulators and various data sheets were (by the time you

read this) exhibited for everyone to handle and inspect at the NIA convention at

Reno in July. Guess we should all be "looking up" during our travels

so we'll have a chance to see these new items in action. Once again, many thanks

to Matt Grayson for steering us onto this report and to Hendrix Wire & Cable

Corp. for graciously furnishing us with the information and samples for the

report and exhibit.

Scott Given (Lodi, Ohio) received letter confirmation from Ohio Brass

Company that they use the new O-B logo on only new lines of items and that means

not on pin type insulators.

Dear Jack:

I recently found a U-206 transposition insulator on an old series street

lighting circuit the power company was taking down. The circuit has been in

service for at least 50 years. The insulator is a dark brown or black, has no

markings on it, and looks very crudely made. I was wondering if you might have

any clues as to when it was manufactured, or its manufacturer.

Marvin Suggs

Port Arthur, Texas

- - - - - - - - - -

Dear Marvin:

The U-206 originated with Ohio Brass Co. and was first cataloged by them in

1912. An engineering notice (unfortunately undated) indicates this item was

subsequently discontinued from manufacture, but it was still in the 1919 O-B

catalog.

The earlier version was U-206A with a shorter skirt and a much bulkier crown

portion and with a very heavy O-B embossed on the edge of the crown. These exist

with a light, bluish-gray glaze in addition to the mahogany browns.

Later versions are U-206, known to me only in various brown glazes which run

to the extreme of essentially black. These have an O-B embossed marking on side

of the top crown portion, but this can be faint to undetectable at times.

Westinghouse in the 1920's continued on with Pittsburg's styles (U-202

transposition) but by 1939 had adopted one transposition approximating the

U-206. It has a much smaller and flatter top crown portion than did the O-B

ones, and my specimen is an unmistakable dark chocolate brown glaze and with a

prominent incuse Westinghouse marking on the skirt.

Putting all the above facts together indicates that May wheat will probably

go to 345 and that you have an O-B tramp of about 1920 vintage.

Jack

Dear Jack:

... Also, does the marking of the U-441 Fred M. Locke effect the $80

value you have in your book? If so, which marking is most desirable?

John & Karen Sanville

Broomfield, Colo.

- - - - - - - - - -

Dear John & Karen:

The listed U-441 value is based on any marking showing it to be a Fred

M. Locke item. Even though we know these were made in the Fred Locke era at

Victor, an unmarked one would be drastically deflated in value.

Jack

Matt Grayson (Roslyn, N.Y.) has for quite some time been using his

spare time away from his college studies to methodically go through the old

Journals of the American Institute of Electrical Engineers (AIEE). He's

concentrated on the particular years which might give answers to questions we've

had on early porcelain and glass insulators. He has recently sent a large stack

of prints of AIEE articles which potentially have new information, and here's a

sample.

In one period (roughly 1903), there were numerous meetings and seminars dealing

with the problem of burning (charring) of the wooden insulator pins just below

the insulators. The point of interest to me was that this was evidently a

serious and widespread problem, whereas I previously thought maybe they were

just overplaying it in the ads promoting use of the porcelain-based pins and the

steel pins

Mr. Etheridge was an active participant in these discussions, so it is not

surprising that Etheridge insulators and their steel pins were pictured and

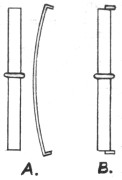

described several times. Since I never had the full Etheridge patent of 6-25-01,

this was the first time I found out just how the pin system worked on it. I've

sketched at the right what the pin and spring insert looked like (A) and what it

looked like with the spring in place (Figure B). The following is Etheridge's

own description of its use:

"... It consists of a malleable iron tube 1-7/16" outside diameter

and 1-1/8" inside diameter. On the outside of this tube-pin is cast a

shoulder on which it rests when placed in the cross-arm. To lock this tube-pin

to the cross-arm a flat high-carbon steel spring -- on each end of which is

formed a gib -- is driven through the pin until the bottom end springs out over

the bottom end of the pin and cross-arm.

"The insulator, which has a plain hole to receive the pin, and a recess

at the bottom of the hole to receive the top gib of the spring, is then forced

down over the pin until the top gib springs out into the recess in the

insulator. This combination very securely locks the insulator to the pin and the

pin to the cross-arm; to unlock, place a screw-driver between the lower gib and

the pin, force the gib back and drive the spring out through the pin

again."

I doubt that anyone will ever find an Etheridge pin from bygone days, but

this description should make it possible for those who have Etheridge insulators

to make a pin and spring from scrap materials to complete their display.

One article of 6-30-98 concerned high-tension insulators in various systems

and testing applications in the field, and it came close to hitting the jackpot

for info on a couple of insulators -- glass and porcelain.

One test line was in Telluride, Colorado On a transmission line of 2-1/4

miles length, and a direct quotation from the test report indicates even tests

were in progress from December 1895 through mid-1896 and later. The line used

two glass insulator styles and one porcelain insulator style on the

double-circuit, three-phase line (6 insulators total per pole). The actual poles

are shown in one picture, plus a close-up of each insulator style with the

dimensions drawn in for each insulator.

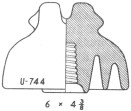

Guess what the porcelain one was ---- Wow, the U-744. We have never been able

to attribute this early style to any manufacturer, but I have on numerous

occasions said I thought it most certainly was made by either Peru Electric Mfg

Co. or G.E. (Schenectady) before the era of Imperial-Locke-Thomas

insulators. The 1895-1896 dates of the Telluride tests with this insulator seem

to indicate I was on the right wavelength.

Now, guess what the two glass styles were. Well, the CD-287 for one (Ho-hum)

but ------ Wow, again, the CD-244 for the other one. That might be new info for

a lucky owner of an SCA specimen of CD-244. In case any of the rest of you want

to prospect for more of these jewels, the 2-1/4 mile line ran from the old power

station near Ames (a few miles from Telluride) to the Gold King mill. In event

you live in California and want to do your prospecting there, they said,

"The large glass insulator [CD-244] is the same as that used on the circuit

in the San Bernardino and Pomona plant."

It may be of interest to some that the tests for several days in December

1895 were with 25 Kv and 33 Kv. This was then increased to 45 Kv for one

continuous week in January 1896, and then to 50 Kv for a continuous run of 37

days in March 1896! Although the voltages were probably elevated so high only

for the purpose of the "testing", I think most utility people today

would say you were nuts if you told them a line with 62 poles of CD-287

insulators was operated at 50 Kv at that altitude and with all that rain and

snow.

Another report of 2-26-04 concerned construction practices on European

transmission lines, and there were several interesting points.

The Europeans considered The U.S. porcelain insulators quite inferior to

European units. Some U.S. shipments were totally rejected piece-by-piece by the

inspector for visual defects -- even though the insulators were o.k.

electrically. They had an aversion to accepting glazewelds or cemented

multiparts because they felt the individual pieces had to be tested separately

to locate defectives. They preferred to test all the parts and then assemble

them in the field.

They cemented insulators to pins and noted, "no attempt is ever made

here to use threaded insulators, as it is difficult to obtain good insulators

with thread of the exact gauge."

Various insulators were pictured in the article, and I had quite a surprise

when turning a page and seeing the one pictured at the right. (By scaling a

metric dimension shown for the height of the central part, it gave the

insulator's diameter as about 7-1/2".) The crown shape was typical of other

insulators shown.

If you'll dig out your copy of the November 1974 issue of Crown Jewels

and look on page 15, you'll see that we ran a report of the insulator pictured

at the left below. Note that the top shells of these two insulators are

essentially identical. Some variation could stem from the facts that the

insulator line drawings in the AIEE Journal were sometimes only fairly accurate,

and the California specimen was drawn from dimensioned sketches without it being

in hand here.

You see, I couldn't help but remember the 1974 report of the California

specimen, since I have always been very curious as to its origin. It was always

clouded in deep mystery, and I couldn't even find out who turned it up -- or

where it turned up first! It became even more firmly implanted in my memory when

I learned that it had subsequently traded hands at a San Diego insulator show

for the unbelievable price of $2500.00! That seems to me to be a helluva steep

price for an insulator when neither the seller or buyer knew anything about it

at the time -- its manufacturer, vintage, use, or whatever. I was told that the

agent of the anonymous buyer, after a series of very secretive phone calls, met

the buyer on a dark street corner where the insulator and cash finally changed

hands. Naturally we've heard nothing of the specimen since then.

Many thanks to Matt Grayson for all this info, and we'll have more coming on

it in upcoming issues.

|